Объективы тепловизионных камер

Эта статья представляет собой базовое введение в объективы тепловизионных камер, которые относятся к оптическим компонентам, используемым для инфракрасной тепловизионной съемки.

Прежде всего, прежде чем понять, что такое объективы тепловизионных камер, необходимо разобраться, что такое тепловизор и тепловизионная камера, а также как они работают. Любой объект с температурой поверхности выше абсолютного нуля (-273°C) излучает инфракрасное электромагнитное излучение (то есть излучение с длинами волн свыше 700 нм, но до 1000 микрон). В отличие от камеры видимого света, которая формирует изображение, улавливая видимый свет, инфракрасный тепловизор формирует изображение, определяя температуру объекта. Поскольку тепловизионная система обнаруживает тепло, а не свет, она может использоваться круглосуточно и является пассивным оборудованием без дополнительного излучения, что не раскрывает местоположение пользователя.

Инфракрасный спектр можно разделить на пять категорий в зависимости от диапазона длин волн: Ближний инфракрасный (NIR), диапазон длин волн 0,75-1,4 микрона; коротковолновой инфракрасный (SWIR), диапазон 1,4-3 микрона; средневолновой инфракрасный (MWIR), диапазон 3-5 микрон; длинноволновой инфракрасный (LWIR), диапазон 8-12 микрон; и дальний инфракрасный, который варьируется от 15 до 1000 микрон. Среди них MWIR и LWIR являются двумя основными диапазонами длин волн для тепловизионной съемки. Излучение MWIR и LWIR может проникать через атмосферу и создавать изображения, выявляя температурные различия объектов, помогая нам лучше исследовать окружающую среду в тумане или ночью.

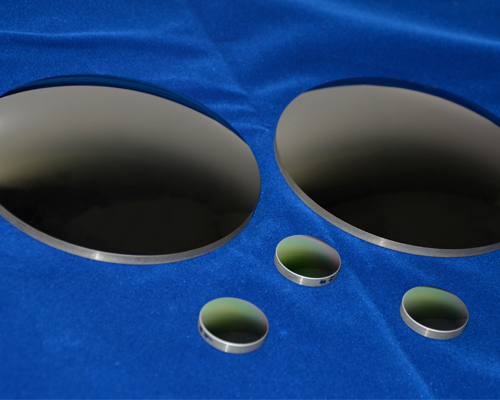

Рисунок 1. На изображении представлен пример тепловизионных объективов компании Shalom EO

Чтобы подробнее понять принцип работы, тепловизор или тепловизионная камера использует оптику для фокусировки инфракрасного излучения от объектов сцены на инфракрасный детектор, после чего цифровые данные от каждого элемента детектора преобразуются в стандартный видеоформат, который можно просматривать на обычном видеомониторе или записывать на видеоленту. Детекторы внутри тепловизоров делятся на две категории: охлаждаемые фотонные (квантовые) детекторы и неохлаждаемые тепловые детекторы. Детекторы тепловизоров служат для приема теплового излучения, поступающего через объективы тепловизионных камер, и формирования визуального представления температурных различий. Поэтому собственное нагревание детектора увеличивает тепловой шум и приводит к потере чувствительности. Охлаждаемый фотонный детектор вызывает прямой электрический эффект после поглощения инфракрасного излучения, тогда как тепловой детектор вызывает изменение температуры после поглощения инфракрасных волн, что приводит к электрическому эффекту. Свойства материалов детекторов влияют на то, как изменение температуры индуцирует электрический эффект. В сравнении, охлаждаемые фотонные детекторы более чувствительны. Они часто оснащаются охладителем для поддержания температуры детектора на уровне -130°F или ниже, обеспечивая высокую чувствительность. Охлаждаемые квантовые детекторы часто используются в тепловизорах MWIR. С другой стороны, неохлаждаемый тепловой детектор не содержит устройства температурного контроля и может страдать от потери чувствительности, но будет значительно дешевле охлаждаемого детектора и достаточно хорошо работает при комнатной температуре. В большинстве случаев неохлаждаемые инфракрасные FPA-детекторы/сенсоры предназначены для использования с объективами тепловизионных камер LWIR, работающими в диапазоне 8-12 микрон.

При проектировании и производстве инфракрасных объективов используются материалы, отличающиеся от материалов объективов видимого диапазона. Материал должен быть прозрачен для интересующего диапазона инфракрасных длин волн. Например, кремний не является хорошим выбором для объективов тепловизионных камер LWIR, так как кремний непрозрачен для длин волн выше 7000 нм. Помимо материалов, важно учитывать и другие факторы, такие как угол обзора, вес, размеры и механизмы фокусировки инфракрасных объективов.

Рисунок 2. Одиночная инфракрасная германиевая линза от Shalom EO

Набор готовых модулей объективов тепловизионных камер состоит более чем из одной линзы. Группа отдельных ИК-линз из различных материалов (например, материалы с дополняющими коэффициентами теплового расширения часто объединяются в один модуль для реализации пассивной оптической атермализации) формируется и проектируется с учетом их функций (например, двояковыпуклая линза для сбора и фокусировки теплового излучения при компенсации сферических аберраций, плоско-вогнутые линзы для рассеивания или коллимации излучения, ахроматические двойные линзы для устранения хроматических аберраций и т.д.). Всё это тщательно отбирается и проектируется в соответствии с задачами оптических сборок.

Кроме материалов, есть и другие ключевые параметры, которые определяют функции и возможности инфракрасных объективов, включая размер и разрешение сенсора, глубину резкости (DOF), фокусное расстояние, угол обзора (FOV), светосилу (f-number), пропускание материалов, искажение изображения, функцию передачи модуляции (MTF), сферическую аберрацию и кому. Подробнее об этих терминах читайте в нашей технической статье Руководство по выбору объектива.

Tags: Объективы тепловизионных камер